Quarrying Techniques - The Quarry and

Blasting

(It is very important to bear in mind that since

the quarrying was a Welsh language industry, the

translations into English are only meant to give an idea of the

meaning of the original. These English versions are modern

literal translations. It is important to know that the

terminology did vary to some extent from area to area. The terms

used here are in the main from the Llanberis area.) (It is very important to bear in mind that since

the quarrying was a Welsh language industry, the

translations into English are only meant to give an idea of the

meaning of the original. These English versions are modern

literal translations. It is important to know that the

terminology did vary to some extent from area to area. The terms

used here are in the main from the Llanberis area.)

It is claimed that it was Richard Pennant, the first

Lord Penrhyn, who was responsible for the

idea of working his quarry using ponciau (galleries)

linked to other ponciau with bariau (rails) running

down the gelltydd (slopes) from one bonc

(gallery) to the other for the car cyrn (lit. horned

cart a cart with two iron bars at the front to prevent the load

of pileri (pillars) and clytiau from falling off.) In some

quarries, a blondin or winsh (aerial ropeways) were

used, (so named after Blondin the great tight rope walker.) This

wire rope ran above the quarry or sinc to lift loads of

rubble or slate. Steam power was used to work these before the

advent of electricity. All of the ponciau would be given

names of a most interesting character like Abyssinia,

California, Giarat, New York, Edward Jones, Robin Dre, Ruban

Glas and Wembley to note but a few.

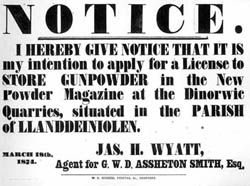

Blasting

Powdwr Du (Gunpowder) was used

every time since dynamite or gelignite would shatter the slate.

The gunpowder was stored in the ty powdwr or cwt

powdwr, (magazine) and before entering one had to wear copper

soled clogs to lessen the danger of striking a spark. A bag

powdwr (lit. powder bag) made of cloth or rubber was used to

carry the gunpowder to the quarry face for blasting. Of course,

dynamite or gelignite was used to blast away rubble to get at the

slate. Powdwr Du (Gunpowder) was used

every time since dynamite or gelignite would shatter the slate.

The gunpowder was stored in the ty powdwr or cwt

powdwr, (magazine) and before entering one had to wear copper

soled clogs to lessen the danger of striking a spark. A bag

powdwr (lit. powder bag) made of cloth or rubber was used to

carry the gunpowder to the quarry face for blasting. Of course,

dynamite or gelignite was used to blast away rubble to get at the

slate.

Before the age of pneumatic drills the jympar (lit. jumper,

a long weighted rod [usually around 2m, but could be

longer]. It was used repeatedly thrusting to bore a shot

hole.) About 15cms from one end is a ball of iron to produce

extra weight. The jympar is used, by thrusting its short

end, until the iron ball reaches the mouth of the shot hole. It

is then reversed and thrust repeatedly again until reaching the

iron ball for the second time. Sometimes powdwr du is

placed in fissures instead.

Great care must be taken to powdro (lit. powder)

properly, knowing exactly how much powder to use, but also how

much stamping is required to loosen the rock safely and

not cause injury to anybody. If proper care is not taken the

(hole can fire) – twll yn tanio, causing possible severe

injury. Saethu (lit. firing) can happen five or six times

a day at set hours. When the corn (bugle) is sounded all

the quarry men go to the caban mochal ffiar, (the cabin to

shelter from the fire.) Three minutes later the corn

is sounded again signalling that it is time to light

(tanio) the fuse with either a cigarette or match, (never

by electricity.) After this, all the tanwyr (lit. firers)

run to the cwt mochal ffiar for a smoke or chat. Then

after three or four minutes resounding explosions are heard

throughout the quarry and the sound of tons of rock falling to

the base of each bargen whilst mwg cur yn y pen (lit.

headache smoke) covers everything and everywhere. Each quarry

man has an unexplainable ability to recognise his own particular

explosion. Eight minutes after the first firing call the corn

heddwch (lit. peace bugle) is sounded to signify that the

firing session is over.

|